Please click the link below to get detailed information about the inspection of crimp connections.

Please click the link below to get detailed information about the inspection of crimp connections.

The term crimping means to press, make an impression, fold or deform by folding. In electrical work, crimping is the mechanical compression of a sleeve around a conductor to make a firm mechanical contact between the conductor and the connector. Crimps have to a large extent replaced soldered connections, and have proven extremely suitable over the years in which they have been in use. They are only permitted, however, if they satisfy the applicable DIN, SAE or customer requirements. To do this, the conductor, contact, crimping tool and tool setting must all be coordinated.

This material is made available for reference purposes only. Rennsteig assumes no liability for its usage and recommends that the user confirm results with their own crimp testing, due to the large number of interacting variables in the crimping environment and manufacture.

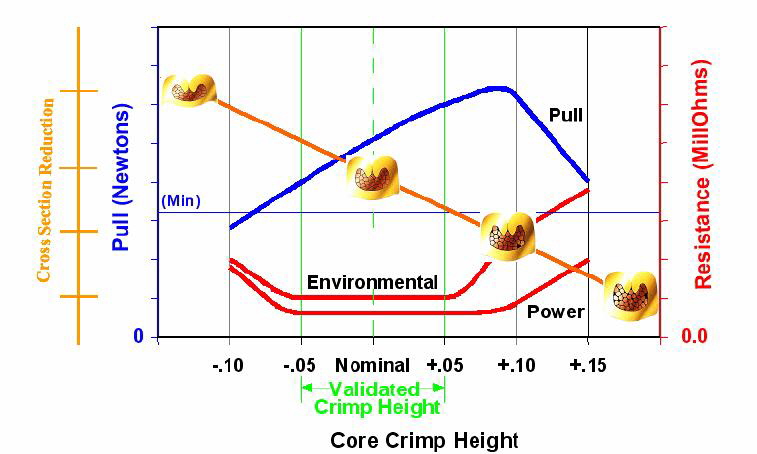

Crimping is inherently a mechanical process that must meet electrical requirements.

Make sure the proper inserts, terminal holder, and wire stop are used for the intended terminal and wire gauge size. Check the tool numbers, terminal name, and wire gauge sizes on tool parts, and check the terminal part numbers and cable gauge sizes from authorized wiring diagrams or other documents. If the cable gauge size is not available, strip a sample of cable to be crimped and verify the gauge size by comparing the outside copper core diameter to the charts.

Use the USA Delphi Terminals Cable Gauge Identification Reference when available. Look at the backside of the insulation crimp and read the cable size that the terminal is designed for.

Here you will find a cross reference between MM and Inches.

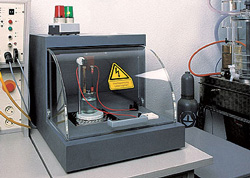

We started to provide step-by-step instruction videos for our customers to show everyone how easy it is to work with our tools. Visit Our YouTube Channel! Click on the link below and see our tools in action!

Dielectric strength is the insulating characteristic of a material which prevents voltage breakdown or flashover. It is measured at voltage per millimeters of the insulation thickness.

As a gas-tight connection is one where the conductors and connectors are so tightly deformed and compressed together that there are no cavities between them. Neither a liquid nor a gas-type medium can penetrate the crimp in normal atmospheric conditions.

Check out this excellent source of information written by Mike Noonan. This book contains exactly the info you need if you plan the use of a modern GM PCM for my older vehicle / muscle car. It's not just another "LS" engine swap manual. The book also features plenty of photos of factory tools and side-by-side comparisons with our products. (Chapter 13)

Check out this excellent source of information written by Mike Noonan. This book contains exactly the info you need if you plan the use of a modern GM PCM for my older vehicle / muscle car. It's not just another "LS" engine swap manual. The book also features plenty of photos of factory tools and side-by-side comparisons with our products. (Chapter 13)

It’s a great example how to use our tools.

Check out this excellent source of information written by Mike Noonan. Automotive enthusiasts who have followed hot-rodding trends over the last decade know that GM’s LS-series engine is the most popular swap on the market. Similar to the first-generation small-block Chevy engines that were swapped into Model A Fords back in the day, these swaps are arguably just as popular.

Check out this excellent source of information written by Mike Noonan. Automotive enthusiasts who have followed hot-rodding trends over the last decade know that GM’s LS-series engine is the most popular swap on the market. Similar to the first-generation small-block Chevy engines that were swapped into Model A Fords back in the day, these swaps are arguably just as popular.

Here you will find an overview about different crimp shapes.

Please send your request to This email address is being protected from spambots. You need JavaScript enabled to view it. with the following information.

Name

Company

Address

Phone

E-mail address

Thanks in advance.